Use Cases

Transforming Infrastructure Decisions Through Real-World Applications

Monitoring, Asset Management & Risk Reduction

⚠️ Challenges:

Traditional inspection and reporting data is subjective, making it difficult to understand where defects are changing, and which defects should be prioritized for repair. Owners lack visibility into how structures are changing over time, creating uncertainty in decision-making.

✅ How Niricson Helps with AUTOSPEX®:

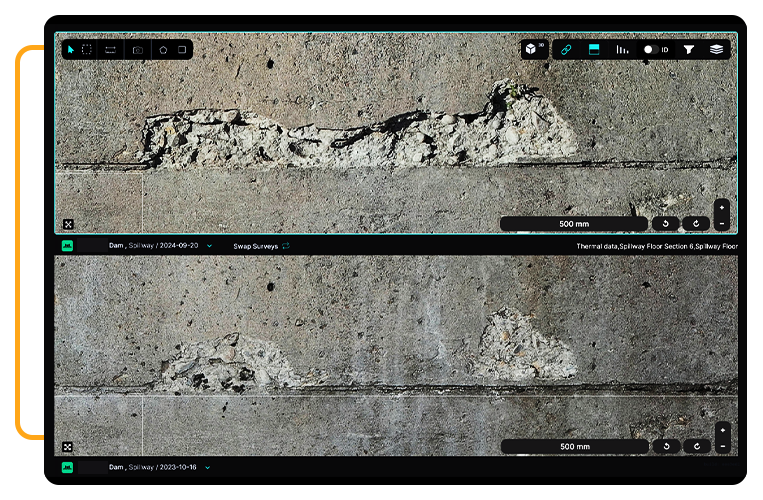

With AUTOSPEX®, each inspection cycle builds on a digital baseline. The Change Detection feature highlights even subtle crack growth, spall expansion, or delamination spread between surveys. Comparison Mode provides side-by-side visualization of current versus past conditions. This provides objective data to owners to justify the need for repairs and similarly can be used by owners to justify that repairs can be delayed or canceled. AUTOSPEX can also help prove to regulators and other stakeholders that maintenance is not necessary by showing that defects are not changing.

This overall enables owners to prioritize interventions, track deterioration rates, and move from reactive maintenance to predictive asset management.

Rehabilitation & Repair Estimates and Prioritization

⚠️ Challenges

Concrete Repair and rehabilitation projects frequently run into unexpected cost overruns, frustrating owners and budget holders. This often stems from incomplete existing condition surveys and incomplete quantities.

At the same time, funding may run short for owners to rehabilitate the entirety of an asset at once, meaning they may need to prioritize specific structural elements or portions of the structure to rehabilitate first, before the remainder can be completed.

✅ How Niricson Helps with AUTOSPEX®:

AUTOSPEX® provides detailed defect maps, surface area of defects, and depths of material loss. These datasets can easily be tabulated per structural element to objectively measure which portion of a structure has the most deterioration to help owners prioritize certain portions of the structure for repairs if funding is limited.

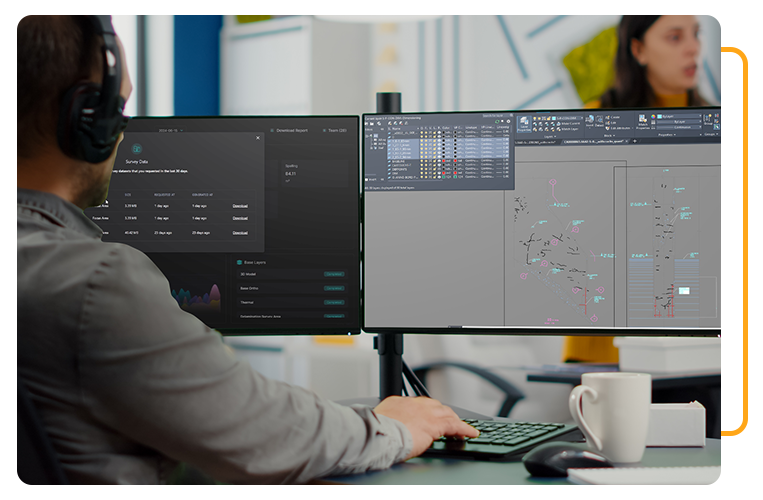

Furthermore, the quantified defect maps can easily be overlaid onto .DWG files in AutoCAD to inform accurate repair scoping in tender documents. This minimizes budget surprises and creates more predictable, data-driven cost planning.

Repair and Rehabilitation Warranty Inspection

⚠️ Challenges

While repairs and rehabilitations often perform as designed, instances of poor repair and rehabilitation performance are not uncommon. Problems with repair design, workmanship, and material mismatching with structural needs can all contribute to missed repairs or pre-mature failure.

✅ How Niricson Helps with AUTOSPEX®:

Repeat inspections analyzed in AUTOSPEX® confirm whether repairs were effective. Change Detection automatically flags areas where defects persist or recur, and Comparison Mode makes before-and-after repair results easy to visualize and share.

This gives owners concrete evidence to enforce repair warranties and ensure work is durable, avoiding costly early rework. This also provides objective data for owners to use to justify certain repair contractors, as well as certain repair methods and materials.

Construction Warranty Inspection

⚠️ Challenges:

Newly built infrastructure often involves different designs, concrete technology, material mixes, and workmanship. While many construction defects may not be significant, construction defects such as ‘through cracks’ on critical structural elements, or the location and size of cracking relative to restraining elements and tensile forces can raise concerns about construction design and can be important information in a design-side analysis after construction.

Furthermore, without a proper baseline of their new assets, owners face significant challenges when managing the delivered asset in understanding whether defects formed during construction, if defects are progressing, or whether new defects are forming.

✅ How Niricson Helps with AUTOSPEX®:

Using high-resolution data from DRONIC™, Niricson processes results through AUTOSPEX®, our AI-powered defect detection platform. AUTOSPEX® automatically maps and quantifies cracks, spalls, and other defects, with the ability to measure cracks down to 0.1mm.

By establishing a digital baseline at project handover, future inspections can be compared side-by-side using Change Detection and Comparison Mode – providing clear, defensible evidence if defects worsen during or beyond the warranty period. For example, cracks may continue to form even years after concrete placement.

Documenting cracks within 2 to 3 months after casting can inform design-side analysis of potential tensile strains developing during the casting process