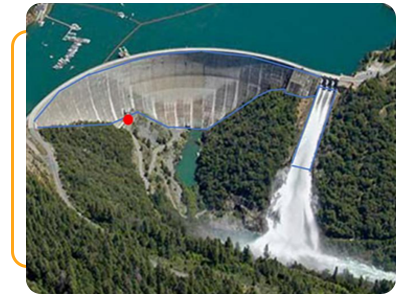

Preliminary condition assessment of

NEW BULLARDS BAR DAM

YUBA WATER AGENCY | YUBA COUNTY, CA, USA

The New Bullards Bar (NBB) Dam is a double arch concrete dam on the North Yuba River, constructed in the late 1960s. It forms the New Bullards Bar Reservoir and is a critical component of California’s water management and hydroelectric infrastructure. Ensuring its long-term safety and performance is essential for water supply, flood control, and energy generation in the region.

The Challenge

While the New Bullards Bar dam and spillway structure are in satisfactory condition, state and federal regulators such as the California Division of Safety of Dams (CA DSOD) and the Federal Energy Regulatory Commission (FERC) encourage risk-informed decision making, comprehensive monitoring, and detailed reporting on potential failure modes (PFMs) to reduce risk. Some potential failure modes may be hydraulic jacking, alkali aggregate reaction (AAR), arch ring cracking, or cavitation in the chute.

While some of these PFMs are easily identifiable and monitored, some can be more challenging. The dam’s large scale and aging concrete structures present inspection challenges, particularly for areas that are difficult to access such as the downstream face and spillway. Furthermore, the subjective nature of traditional inspection methods (visual, rope access, scaffolding, bucket trucks) mean that identifying changes on the structure can be challenging.

Our Approach

Timeline

Data collected between April 17 and May 3, 2023. Data processed between May 3 and September 2023.

Technologies Used

- AUTOSPEX® (AI-powered defect detection and quantification software)

- DRONIC® (multi-sensor UAV data collection technology: optical, infrared, acoustic)

- Acoustic base station and NCX acoustic hammer technology

Execution

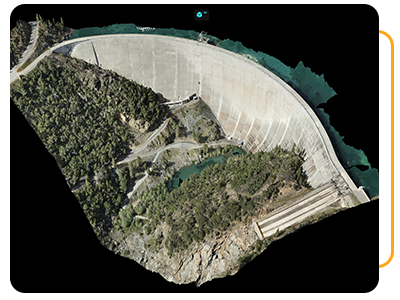

- High-resolution RGB images to map visual defects for the downstream arch.

- Thermal, high-resolution RGB, and acoustic concrete soundings were collected from the spillway structure to identify cavitation, leakage, and delamination.

- Defects were automatically detected and quantified in AUTOSPEX®, including cracking, spalling, and delamination.

- Historical datasets (2018 and 2021) were reprocessed and compared with 2023 data, enabling change detection and condition trend analysis.

Workflow

Data capture → Pre-site departure quality control → Multi-sensor processing → AI-based defect detection → Post AI defect mapping quality control → Web-based visualization and reporting via AUTOSPEX® platform

Results and Impact

Key Outcomes:

Through this project, Yuba Water Agency now has a comprehensive, data-rich digital model of the New Bullards Bar Dam. This data supports YCWA’s Dam Safety Surveillance and Monitoring Plan (DSSMP), to help monitor potential failure modes and provide more objective condition assessment data in alignment with RIDM. As a result, the data reduce risk, improve preventive maintenance, and provide visibility for long-term asset management. This proactive approach ensures the dam continues to operate safely, sustainably, and reliably securing water resources, hydroelectric power, and public safety for decades to come.

By deploying this technology through multiple scans, the information enables YCWA to proactively detect and address deterioration and enhances confidence in prioritizing repairs on the structure by targeting defects that are both risky and contribute to a potential failure mode.