However, not all repairs perform as intended.

Design limitations, workmanship issues, or incompatibility between repair materials and existing substrates can lead to premature deterioration. In many cases, these problems are only discovered years later, after warranties have expired and additional damage has progressed. The result is costly rework, operational disruption, and avoidable risk.

To truly protect infrastructure investments, asset owners need more than visual confirmation. They need objective, repeatable evidence.

That is where AUTOSPEX Change Detection delivers measurable value.

The Challenge with Traditional Warranty Inspections

Conventional post-repair inspections often rely on:

- Visual walkdowns

- Photo documentation

- Sample-based surveys

- Subjective condition ratings

While these approaches provide insight, they can lack precision and consistency. Subtle defect recurrence may go unnoticed. Quantifying crack growth over time can be difficult. Demonstrating whether a repair truly performed as specified becomes challenging without a defensible baseline.

When enforcing repair and rehabilitation warranties, ambiguity works against the asset owner.

What is needed is a digital record that captures the asset before repair, after repair, and at defined intervals moving forward.

Establishing a Defensible Baseline

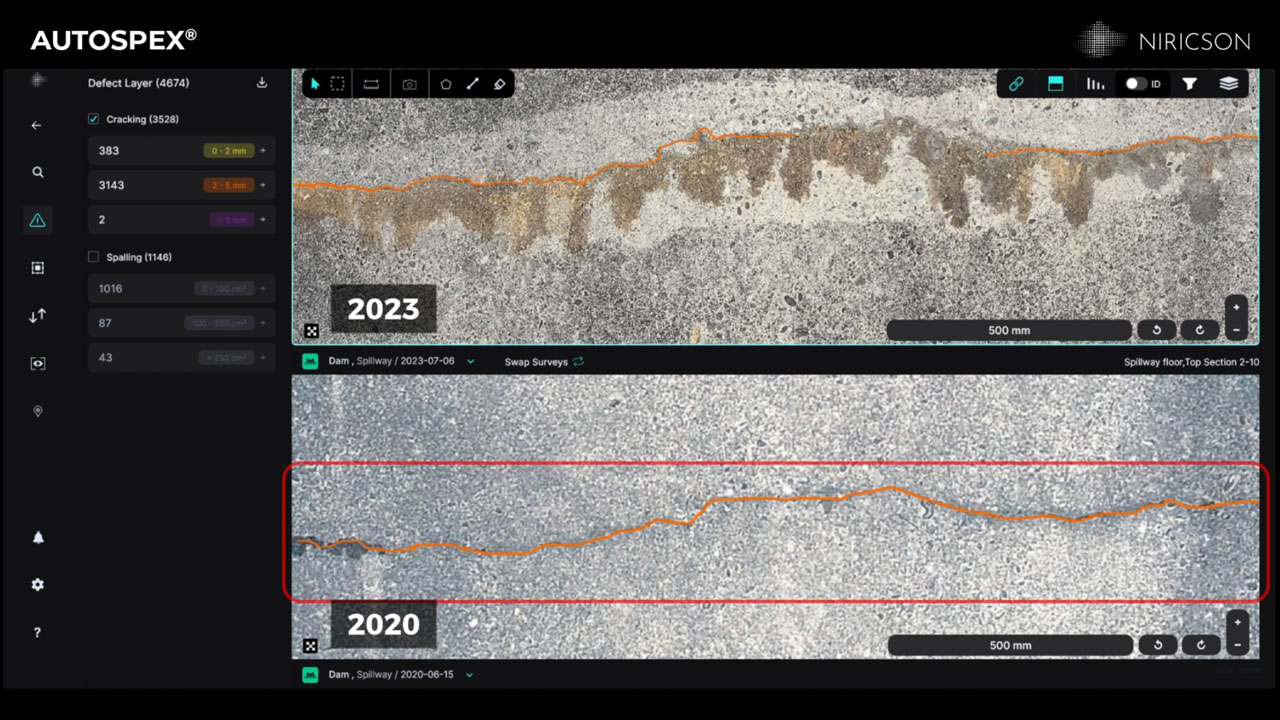

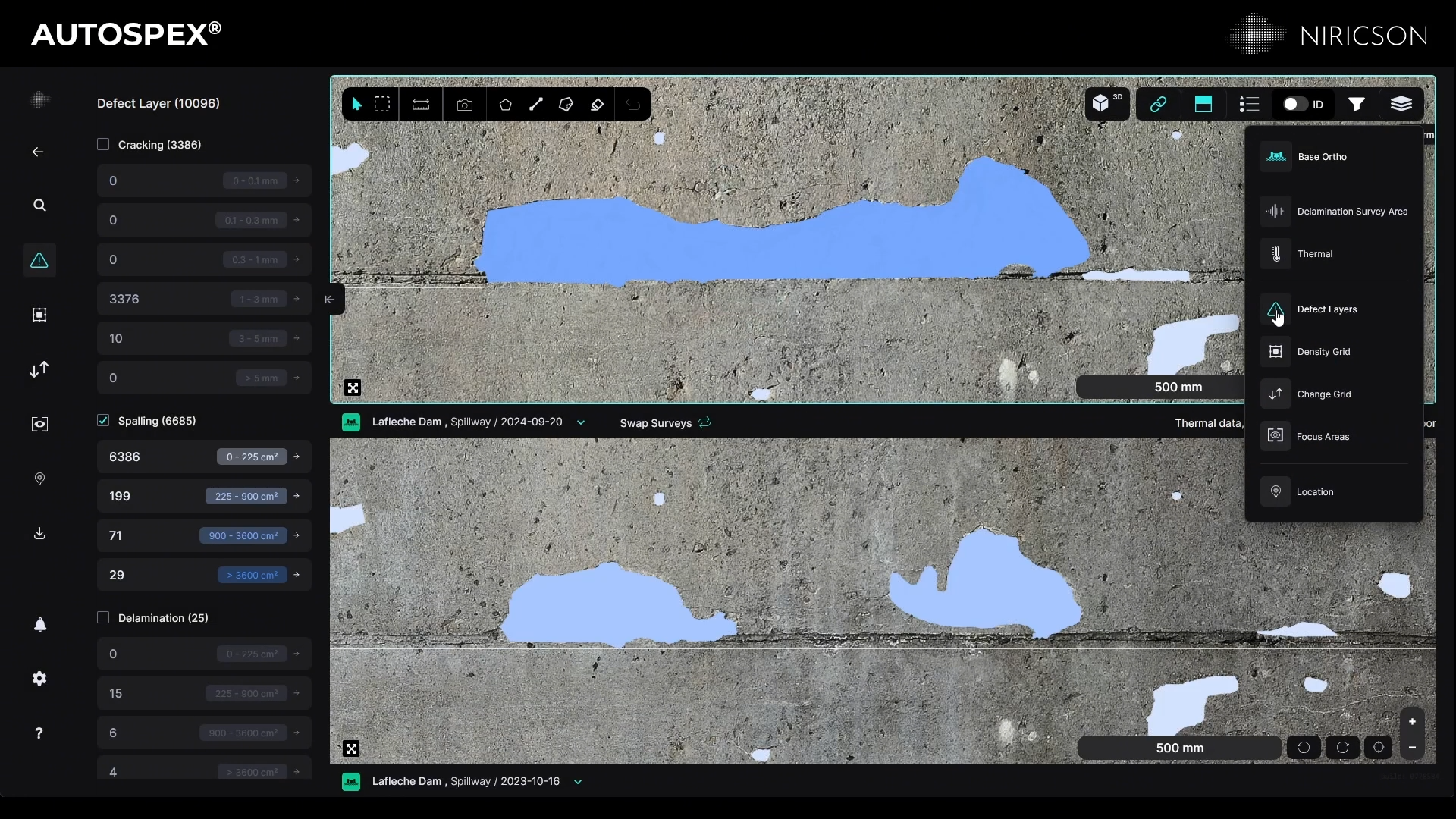

With repeat digital inspections, AUTOSPEX establishes a high-resolution baseline of the structure. This baseline becomes the foundation for all future comparison.

Using AI-powered defect detection and measurement, AUTOSPEX enables asset owners to:

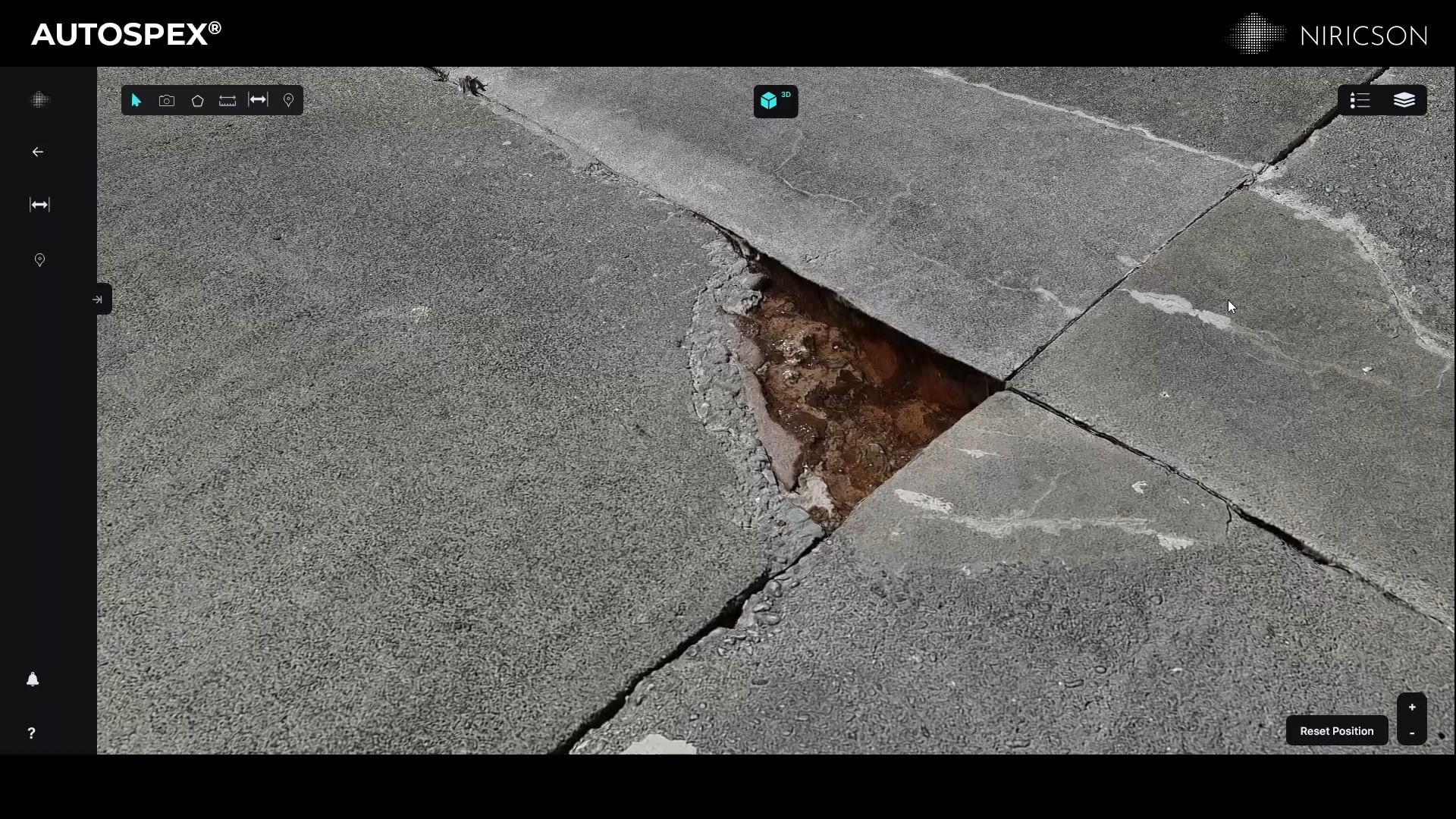

- Digitally map cracks, spalls, delamination, and other surface defects

- Quantify defect dimensions and severity

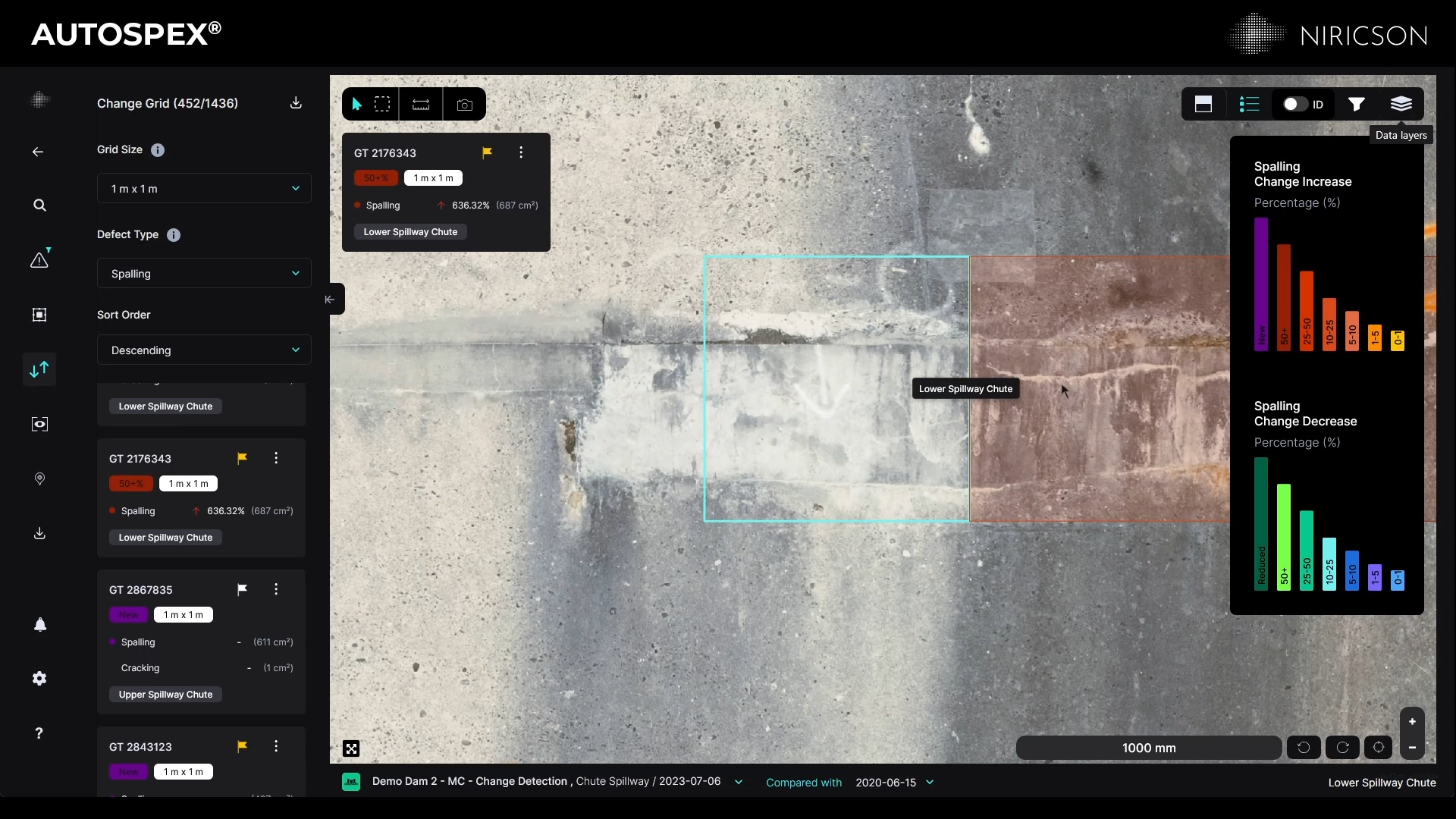

- Track deterioration progression over time

- Identify newly formed defects with precision

Instead of relying on memory or static photographs, owners gain a time-indexed digital condition history.

Quantifying Repair Performance

- Repair verification should not be subjective. AUTOSPEX enables quantification, including:

Crack growth measurement over time - Surface area change of spalled regions

- Identification of new defects adjacent to repaired zones

- Confirmation of defect stabilization

These quantified trends allow asset owners to determine whether repair strategies are truly effective.

If deterioration continues, corrective action can be taken early. If repairs perform well, confidence in specific methods, materials, or contractors increases.

Enforcing Warranties with Objective Data

Warranty enforcement requires proof.

AUTOSPEX provides structured, repeatable data that supports:

- Validation of contractor performance

- Evidence-based warranty claims

- Documentation of repair durability

- Justification for selecting specific repair methods in future projects

When conversations shift from opinion to measured data, outcomes become clearer and more defensible.

Reducing Risk and Protecting Investment

Every repair program represents a significant investment of capital, time, and operational coordination. Verifying long-term performance is not just about compliance. It is about protecting that investment.

By combining AI, machine learning, and digital condition assessment, AUTOSPEX transforms inspections into actionable insight. Asset owners can:

- Reduce uncertainty

- Detect recurring issues earlier

- Support data-driven maintenance planning

- Improve long-term lifecycle management

Rather than discovering failures years later, owners gain continuous visibility into how their infrastructure is evolving.

Turning Inspections into Evidence

Repairs are only as good as their long-term performance. With AUTOSPEX Change Detection, inspections move beyond snapshots in time and become part of a measurable, defensible condition history.

From before-and-after comparisons to quantified deterioration trends, AUTOSPEX turns inspection data into evidence you can trust.

See infrastructure changes like never before with AUTOSPEX®.